A taper is what defines a

rod's action. Action is the way in which a rod flexes during casting.

By modifying the diameter of a rod throughout its length,

one can make rods with massively varying degrees of actions.

Tapers are designed in many ways. Trial and error are always

the final factors in determining whether a rod is 'good' or

not, but there are other ways of creating and modifying

tapers.

Everett Garrison, being an engineer, created a way to look

at bamboo rod tapers by graphing the static stress at each point

along a rod's length. The stress values of a rod are

computed by taking many variables into account including the

weight of the bamboo, finish, guides, ferrules, etc. plus

the diameter of the rod along points along its length. From

the resulting stress curve charts, it is fairly easy to

visualize the action of a rod using strictly the taper

measurements.

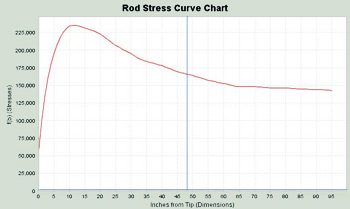

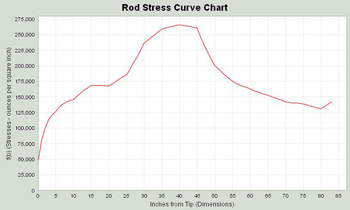

Stress curve charts, or simply stress curves, are graphed as

follows. A rod's tip is represented on the left side of the

graph along the X axis, and the butt section is on the

right. The Y axis contains the computed stress along each

point of the rod. Basically, the higher the point, the

softer, or more flexible, it is at that point on the rod. |

| To the right is a

stress curve chart for a Powell B8.7 straight taper

- one whose diameter changes a uniform amount of

.0145" for each 5" along its length and whose tip

dimension is .070" |

|

|

|

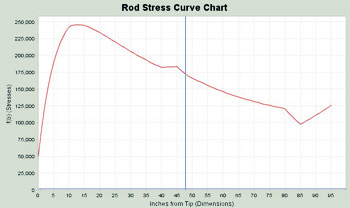

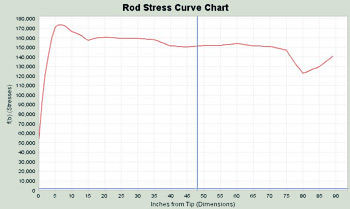

Compound tapers are

ones that are not straight tapers, or tapers that

get slightly wider or more thin at various points

along the length. Almost all bamboo rods are built

off of compound tapers. As an example, a fast action

rod is one that has a relatively soft tip and a

stiffer butt section, where most of the rods flex is

in the uppermost section(s) of the rod. A faster

action bamboo rod stress curve chart will often look

something like the graph for a Dickerson 8013 to the

left. |

|

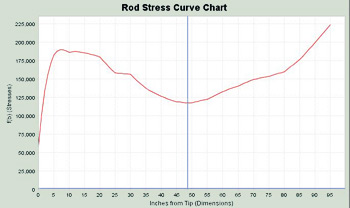

| A 'parabolic' rod is

one that has a stiffer mid section pushed by a

relatively softer butt. The tip can be

anywhere from really stiff to quite soft. The

ubiquitous Paul Young Para 15 is an excellent

example of this type of action. |

|

|

|

To the left is

another rod action that is called 'parabolic'. The

shared characteristic with the Young parabolic rod

above is obviously the relatively soft butt section

and stiffer mid. However, this Pezon et Michel Ritz

Fario taper lacks any softening in the tip section.

This basic curve shape is also seen in the few Payne

parabolic rods that exist. To me, and in keeping

with the general patterns of stress curves, this

shape would be better described as 'slow' action. |

|

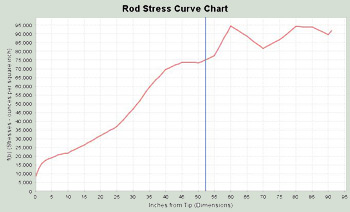

| Though 'slow' is

often used as an equivalent to 'soft' the Orvis 7' 3

weight stress curve to the right is probably a

better example of a slow rod: One with a very

soft, flexible mid section that doesn't show the

characteristic soft butt of a parabolic. |

|

|

|

Garrison used his

stress curve charts to create wonderful medium, or

progressive action rods. Garrison found that tapers

with smooth, horizontal stress curves generated this

type of action, hence all of the stress curve charts

for his various rods show a very similar profile. To

the left is an example of a Garrison 209. |

|

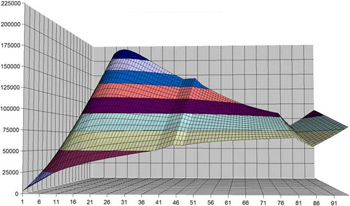

One of the variables

that is used in computing a stress curve is the

'length of line cast' or simply casting distance. By

adding a Z axis to the standard stress curve chart,

which takes into account various distances of line

cast, one can see when a spot on a rod will become

under- or overloaded. To the right is an example of

the Dickerson 8013 from above with the addition of

the line cast from 2' to 50'.

|

|

|

| |

|