Hollow building a

bamboo fly rod means exactly what you'd expect:

Material from the inside of a bamboo rod is removed

leaving open spaces within. The purpose of removing

the material is to make the rod lighter in weight

and make it rebound and recover quicker with less

bounce and excess vibration.

There are many methods of hollow building. Most

methods have disadvantages, the most severe being a

significant reduction in the overall strength of the

rod. I have experimented and made rods with every

type of hollowing I could find - straight-cut,

fluted, star-hollowing and scalloped. |

|

| Solid Cross

Section |

|

|

| Straight-cut Hollow |

|

|

| Fluted Hollow |

|

|

| "Star" Hollow |

|

|

|

After testing these

rods I have come to the conclusion that the best

method, for both improvement in action and overall

strength, is a method first described and developed

by EC Powell.

|

Click here to see Powell's original October 31,

1933 patent. |

Simple scalloping involves removing small ovals of

the softer, inner pith of a beveled and shaped

bamboo strip. By mirroring the ovals on each of the

6 identical strips of a hexagonal rod (or 4 strips

for quads) you end up with small hollow ovals inside

the finished rod. This method of manufacture is, as

a friend put it, the closest to "OEM specs"

of a bamboo culm. In other words, like a culm of

bamboo, there are hollows that are reinforced by

dams throughout the length of the culm.

Of course that is not

the end of the story. The next step is to vary the

length and wall thickness of the scallops, or

hollows, inside the rod in order to improve specific

desirable qualities. Longer, thin wall scallops are

better suited for the thinner tip portions of a rod

while shorter, thicker walled scallops keep butt

sections from becoming weak or too soft. |

|

| I have designed a complex mixture of scallops with

different wall thicknesses, dam thicknesses and

lengths and optimized their layout for each section

of a rod from under the grip into the tip. This gives,

what I believe, is the greatest benefit of hollow

building while retaining the strength and feel of

bamboo. |

|

| This photo shows a side view of

a single bamboo strip that has been

scalloped (approx. 1" long). |

|

|

|

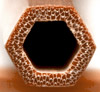

This photo shows what half of a rod

(3 strips from a hex rod in this

case) looks like when scalloped and

assembled. |

|

|

|

|