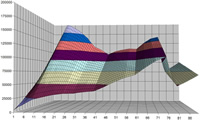

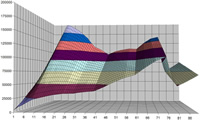

Stress curves are graphic representations of

a rod's taper and are designed to visually represent the

action of a rod under varying degrees of stress which

helps to fine tune the rod's eventual taper.

|

There are various methods of heat treating a culm of bamboo, from open flame to special ovens.

The purpose is to drive out excess moisture and/or alter the color.

I use a combination of flaming and oven tempering in order to change both the tone and resiliency of the cane.

There are various methods of heat treating a culm of bamboo, from open flame to special ovens.

The purpose is to drive out excess moisture and/or alter the color.

I use a combination of flaming and oven tempering in order to change both the tone and resiliency of the cane. |

Splitting the tubular culm into individual strips of useable size is the first step after the culm is treated.

An average culm can be split into anywhere from 12-32 strips. |

Strips are cleaned up and straightened with a heat gun and

then beveled using a special router based machine

to give them their initial rough triangular shape. |

Steel planing forms are set according to the selected taper. The V groove is adjusted

to tolerances within 5/10,000 of an inch. The other option is to use a specially made

motorized beveler designed for shaping bamboo strips. |

Each strip in the rod is then planed and shaped to match the

taper set in the planing form or beveler. |

With the proper tools and adjustment, shavings thinner than 1/1,000 of an inch can

be consistently made. |

A pile of shavings after planing a few rods. Notice the clean curls of bamboo. A

sign that the bamboo was heat treated properly, and the planes were tuned well. |

Once all the strips for a rod section are planed, they are rolled into loose rod sections and taped together, ready for glueing. |

The tape on the rolled up sections is then sliced and the strips

are laid flat, cleaned up and prepped for gluing. Glue

is applied with a brush and, if the rod is hollowed, the

hollows are carefully cleaned of glue. |

After glue is applied, the strips are rolled back togther and bound using a 4-string binder that

is designed to tightly secure the strips without introducing any unwanted torque or twist. After binding

sections are heat-set they are laid aside to cool and cure.

After glue is applied, the strips are rolled back togther and bound using a 4-string binder that

is designed to tightly secure the strips without introducing any unwanted torque or twist. After binding

sections are heat-set they are laid aside to cool and cure. |

The glue, tape and string are scraped and sanded from the blank which is then finish sanded and

sealed to smooth and protect the cane. |

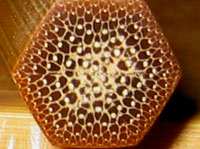

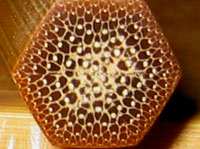

A Cross-section of a cutoff showing the inside of a glued

hexagonal blank with the softer pith

on the inside and stronger, denser, more resilient power fibers around

the perimeter. |

Top quality drawn nickel silver ferrules must be filed and fit to extrememly tight tolerances to get a

proper fit with the requisite and pleasing 'pop' sound when separated. |

The ends of each rod section is then carefully rounded and shaped and the ferrules are securely glued in place. |

The grip is shaped from rings of the finest Portuguese cork and the reel seat is sized and fit. |

Guides are temporarily taped in place and then are wrapped using the best quality and finest silk available. |

|